Starter device

First, let's look at how a starter works:

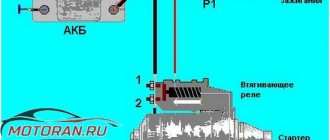

- when the driver turns the key to the extreme right position, current flows to the starter winding;

- the crankshaft flywheel engages with the overrunning clutch gear;

- The crankshaft, rotating, transmits torque to the pistons, the combustible mixture begins to enter the cylinders and ignite through ignition;

- at approximately 100 revolutions the clutch and flywheel are separated;

- after the circuit is opened, the key goes to the middle position, the starter shaft does not rotate.

Schematic structure of the system:

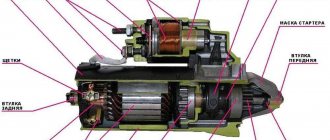

Starter device:

If the starter hums but does not turn the engine, this behavior indicates a wide range of different malfunctions. The peculiarity of the situation when the engine does not start is that there are certain difficulties in localizing the problem: it may lie in the fuel pump that does not turn on after turning the key, in the starter’s refusal to turn the crankshaft, etc. But in the general case, a common phenomenon is when the starter “turns” and turns out to be is able to rotate the crankshaft, but the engine refuses to start.

Checking the condition of the piston group

To look into the cylinders with unscrewed spark plugs, you will need an endoscope. Modern systems are connected to digital electronics, and the image is displayed directly on the screen. With its help, you can assess the condition of the cylinder and piston, see the amount of carbon deposits, due to which they wear out faster.

Using this equipment, you can see damage and scale without disassembling the engine; sometimes there is sand mixed with oil in the combustion chamber, this leads to accelerated wear of the piston. Such damage can also lead to the engine not starting.

Starter malfunction

Before you do an in-depth check of the components, you should make sure that the starter itself is in order. It should work without any extraneous sounds - clicks, hums, etc. The starter electric motor normally operates smoothly, without failures or any omissions. The malfunction is determined by ear, and if the starter clicks but does not turn the engine, the cause is most likely in the starter itself.

Of course, if after turning the key nothing happens at all, this unit also needs to be checked for serviceability. So, the absence of a click clearly indicates a breakdown of the solenoid relay.

If the starter rotates the shaft normally, but the engine still refuses to start, you should check:

- fuel system;

- ignition;

- state of sensors of the electronic engine control system;

- flywheel ring teeth or clutch gears - they may be worn out. This is a common reason why the starter turns but does not turn the engine. The malfunction may also be accompanied by the grinding sound of worn teeth.

These problems can manifest themselves in both “cold” and “hot” conditions. Another reason why the starter does not turn on a hot engine is a malfunction of the power unit: for example, the crankshaft liner is worn, which is pinched when heated, or there is an axial displacement of the shaft. The starter does not turn well on a hot engine if the piston group is faulty, the battery is discharged, the ignition is incorrectly configured and the starter elements are worn out.

It is also possible that the crankshaft cranks too slowly when trying to start. There may be several reasons why the starter turns the engine slowly:

- poorly charged battery that does not produce sufficient current;

- faulty solenoid relay;

- wiring problems;

- The oil is too thick.

The Niva engine does not start. What to do? « NewNiva.ru

January 28, 2021 Lada.Online 158 272 5

Often, owners of a VAZ 2121 or 2131 SUV encounter problems with starting the engine. For example, when you turn the ignition key, the starter does not turn. Let's look at possible problems with the Lada 4×4 starter and ways to solve them.

Silence when trying to start the engine

The Niva crankshaft cannot be turned by the starter.

There may be several reasons:

- Blown fuse.

- Poor contact between battery terminals.

- The battery is completely discharged.

- Failure of the starter solenoid relay.

- Failure of the intermediate relay that switches the starter circuit.

First of all, you should pay attention to the dashboard. When you turn on the ignition or the main electrical circuit in the engine, the lamps should light up on the dashboard or information should appear on the on-board computer, if we are talking about the Chevrolet Niva

If this does not happen, the cause should be sought in the fuse box and in the battery contacts. During operation, oxides may form on these contacts, increasing the resistance. Loose contact connections can lead to sparking and burning.

If no blown fuses are found, you should check the reliability of the “+” contacts of the battery with the central wire and the “-” contacts with the vehicle ground.

To eliminate the malfunction, be sure to replace the fuses and clean the contacts. It would be a good idea to acquire even the cheapest tester in order to quickly check the presence of voltage in the electrical circuits of the car.

Injector problems

Why doesn’t the car start when it’s hot if, for example, it has an injection engine? There are also a lot of problems with such cars, mainly due to sensors, but there are also other problems. There are several options here:

- Coolant sensor malfunction. Since the injection system is almost completely automated, its operation depends on the readings of sensors located in the gas tank, engine and other components. As soon as the reading device produces incorrect information, the entire system begins to malfunction. For example, problems in the readings of the coolant sensor lead to the fact that the ECU, which reads the device information, gives the wrong command to other operating elements. As a result, the wrong amount of fuel enters the chamber, which is why it is impossible to create a combustible mixture. The solution to the problem is to disconnect the sensor, clean it, or replace it if it is damaged.

- Problems with injectors. This is an extremely rare case of malfunction, but it does happen. The breakdown consists of a breakdown of the injector, and for this reason fuel is not supplied. The lack of pressure inside the channel leads to the fact that fuel does not enter the combustion chamber. The injectors need to be replaced.

- Faulty air flow sensor. As in the first case, it can easily fail, which disrupts the operation of the system for creating a combustible mixture. As a result, the fuel is either too rich in oxygen, or, conversely, poor. In both cases, fire does not occur, and therefore the engine does not start. The following symptoms accompany the problem: surges in engine power, strange sounds when starting the engine, the sound of a strong exhaust from the gas exhaust system, failures when pressing the gas. Replacing the device and adjusting the entire system should help.

Clicking noises when trying to start the engine

If all contacts and fuses of the Niva are normal, you should turn the ignition key to the “start” position and listen to see if the relay clicks. If clicking sounds are heard clearly, the problem may lie in the starter voltage relay, the solenoid relay, or the starter coil circuit.

In “male” car services, the serviceability of the solenoid relay is usually checked by closing its contacts with a large screwdriver until the starter begins to rotate. For safety reasons, this should not be done under any circumstances.

If the problem is in the intermediate relay, then it is quite easy to replace it on the Niva. It is enough to insert the new relay block into the terminal block, observing the sequence and polarity of the connection.

To check the serviceability of the solenoid relay, the starter will have to be removed. After this, holding the starter, you should connect it to the battery and apply voltage to the contact of the solenoid relay. If a click is clearly heard, then the solenoid relay is working properly.

If the solenoid relay works, but the starter rotor does not rotate, it is necessary to check the condition of its brushes, which may have worn out so much that they have lost contact with the winding. In this case, repairing the starter costs little money.

Failures outside the starter

Most engine failures with a working starter are due to the fact that there is either “nothing to burn” or “nothing to ignite”. Let's take a closer look at them.

Fuel system

It consists of several elements that should be checked step by step:

- fuel pump (electric or, in some car models, mechanical driven by the engine);

- fuel supply system - carburetor or injector;

- fuel line;

- filters that clean the fuel passing through the highways.

Another possible reason is a disruption in the fuel supply due to the formation of suction in the system; it should be found and eliminated.

An important note concerns diesel engines: if the owner has chosen the wrong diesel fuel in the winter, in the cold it thickens (waxes), and the fuel supply system units simply cannot pump the fuel to deliver it to the cylinders.

Owners of cars with injection engines know that immediately after turning the key you can hear the fuel pump turn on for one or two seconds. Its job is to supply fuel to the system, and if the pump is faulty, the engine will not start. The sound of its operation is a characteristic hum, and when it is not heard, then most likely the problem is in the fuel pump or its power circuits. You need to check the correctness:

- the electric fuel pump itself;

- relay;

- fuse;

- power wires going to the node.

Injection pump VAZ 2109:

Interesting: for injection cars, you should check whether there is fuel in the fuel rail. It has a special control valve, when pressed, gasoline should begin to flow. This will indicate that fuel is present in the ramp and is supplied to the injectors.

If the car is carburetor, then its pump is most likely driven by transmitting torque from the camshaft. To carry out the check, you need to remove the hose going to the carburetor inlet fitting; in addition, the hose can be removed from the pump outlet. After this, use the manual pump lever (located on the pump) to pump up some fuel. If the unit is in order, gasoline will leak out.

Note: the author has repeatedly had to deal with the situation of a fuel pump failure, when the car was driving for quite a long time with an almost empty tank, without adding fuel. The fact is that gasoline at domestic gas stations is not always of high quality; it contains impurities that settle at the bottom of the tank. When the filling of the fuel tank drops, the pump begins to “scoop up” dirty gasoline/diesel with sediment from the bottom, which clogs the pump mechanism, filters, fuel injectors, leading to malfunctions, engine tripping, and a complete inability to start it.

There are often situations when fuel filters become clogged, then the liquid can no longer pass through them normally, and the starter “turns” idle. Filters should be checked and cleaned/replaced if necessary.

Problems with the fuel system

Even the most “vigorous” battery and a new, working starter will not be able to start the car if problems arise with the supply of fuel to the cylinders. For this reason, the next thing to check is the engine power supply system.

1.Fuel pump

For carburetor and diesel engines, this unit is located directly next to the cylinder head or block. Injection power plants are equipped with an electric pump, which is installed in the fuel tank. Their operation is judged by a short buzzing sound that appears after the ignition is turned on. As for fuel pumps in carburetor engines, they are mechanically driven by a cam mounted on the camshaft.

It is easy to check the functionality of the fuel pump - to do this, remove the hose from the carburetor inlet fitting and lower it into a suitable container. After this, you should pump up the fuel using the manual pumping lever or by turning on the starter. If the result is negative, check the passage of gasoline through the fuel line and clean the mesh located in the top cover of the pump. If this does not help, then inspect the membrane and valves of the fuel pump. After replacing damaged and worn parts, the functionality of the device will be restored.

2.Fuel filters

Along the path of fuel passing from the tank to the engine there are several filter units - coarse meshes located on the fuel receiver, in the fuel pump and carburetor, and in addition, paper filters located in the section of the fuel line. The intensity and even the possibility of supplying fuel to the internal combustion engine depends on their purity. If you find a blockage, clean or replace the filter elements.

Throttle and injectors

Gasoline internal combustion engines operate on a fuel mixture, which is prepared in the carburetor or in the intake manifold (for fuel-injected cars). In the first case, the fuel passes through a whole system of channels, jets and nozzles that are located in the carburetor. In the second, it is supplied by injectors according to signals received from the electronic engine control unit (ECU).

The air supply is metered using a throttle valve, which, depending on the engine design, can be mechanically or electrically driven. Clean the parts of this assembly and the throttle itself. Also check if fuel is being supplied to the cylinders. If you are dealing with an injection car, then press the fitting spool located at the bottom of the fuel rail - gasoline should flow out from there under pressure. If the stream is too weak, then check the filters, fuel line and pressure reducing valve of the fuel pump.

In carburetor engines, the fuel supply can be judged by sharply opening the throttle - in this case, a portion of fuel will be injected from the accelerator pump nozzle into the diffuser. In addition, for gasoline power units, inspect the spark plugs - they should not be dry. Otherwise, check for the presence of a control signal at the injectors. If everything is in order with this, then you should unscrew the ramp fastening and move it away from the manifold in order to inspect the spray nozzles when starting the engine. The absence of fuel streams or their weak intensity indicates the need to clean or replace the injectors.

This is interesting: Repairing a car threshold with your own hands without welding

As for diesel engines, fuel is supplied to them under high pressure, and a much more complex pump (fuel injection pump) and specially designed injectors are responsible for this. To repair these components, special equipment is required, so in this case it is better to contact specialists.

Something else useful for you:

- Why does the starter click after turning the ignition key, but the engine does not turn with the starter?

- Causes of alternator belt whistling and how to remove this whistling noise?

- How to check the starter when removed from the engine?

Video: The starter hums, but the engine does not turn over

Malfunctions of electronic systems

To check the ignition system, unscrew and remove the spark plug from one engine cylinder. Having installed the tip of the high-voltage wire on its contact nut, touch the spark plug skirt to the cylinder head and crank the engine with the starter. In this case, a powerful spark of a purple or blue hue should appear on the contacts. If the spark is too weak (or there is none at all), then we check the operation of the computer, ignition coils and distributor (for an old-style internal combustion engine).

Other reasons for difficulty starting when the starter is running

- The timing belt is torn, or is loose and has jumped several teeth - in this case, the valve timing turns out to be off, which is why the engine cannot start. It is enough to replace and mark the belt, unless such a nuisance ended with the pistons meeting the valves - in this case, a major engine overhaul will be required.

- The crankshaft rotates with noticeable force, which may be caused by various mechanical damage to the crank mechanism and the cylinder-piston group. Check whether the engine turns when you try to start it in top gear “from a tow” (for manual transmissions) or by turning the crankshaft pulley on cars with automatic gearboxes. Relatively easy rotation indicates that the cause of the malfunction is hidden elsewhere.

- One of the mounted units is jammed, which creates increased resistance to rotation of the engine shaft. To find the “weak link,” you need to loosen and remove the belt, and then try to manually turn the pump, generator, air conditioning compressor or power steering pump. If the breakdown occurred far from the service station, then you can only get to the nearest car service center in those cars in which the pump is driven by a timing belt. On other engines, you can try to connect the crankshaft and coolant pump pulleys with something suitable - a rope, a rubber strip cut from a car inner tube, etc.

- Failure of sensors connected to the ECU - crankshaft position (CPCV), Hall, etc. Due to their breakdown or incorrect operation, the engine control unit incorrectly regulates the fuel mixture or injects and ignites fuel at the wrong time when it is necessary .

- Sometimes the cause of a failure or incorrect interpretation of signals from a particular sensor is electromagnetic interference from the starter and other electrical units. In this case, it is difficult to identify the malfunction, so it is possible that you will have to turn to specialists for advice.

Ignition problems

So, let's assume that the starter is ok, the fuel system has been checked, but the engine still refuses to start. The reason for this may lie in ignition failures (“nothing to ignite”).

The first thing you should check is the condition of the spark plugs, coils and high-voltage wires going to them (“armored wires”). Their failure leads to the fact that the spark required for ignition does not appear on the candles.

The presence of a spark from an injection engine can be determined by unscrewing one of the spark plugs. This should be removed, then an armored wire should be put on it and the spark plug should be attached with its skirt to the cylinder block.

Important: it is advisable to perform the operation together.

After this, you should turn the starter with the key: if current flows to the spark plug and there is a spark, it will be visible to the naked eye. Spark on the spark plug:

It is important to follow safety precautions and not touch the electrodes! If the spark plug does not react in any way to the starter, it means there are problems with it, the wires or the ignition coil itself. A more thorough check of these elements should be carried out.

The coils can be checked “in the field” by simply swapping the wires. If there is a fault somewhere, such a rearrangement will quickly show them.

Important: the absence of a spark on one or more spark plugs may indicate a general failure in the ignition module, which in such a situation should also be checked.

The coil of a carburetor engine can be checked using another “field” method: remove the central wire and bring its end 5 millimeters closer to the metal surface, then “turn” the starter. There should be a spark; if it is not there, then the coil is faulty. If there is a reaction, but the engine refuses to start, you should remove the distributor cover and check the condition of this unit.

Ignition check

Another reason why the car stalls and does not start, the starter spins at idle, may be incorrect operation of the ignition system. It is quite simple to check its functioning and determine the cause of the problem; just check any of the spark plugs for sparking. To do this, you need to remove the spark plug from the cylinder of the power unit, put a high-voltage wire on its head, and place the skirt 10-15 mm from the engine block. Next, you should ask an assistant to crank the starter. The presence of a spark indicates the serviceability of the ignition system.

We recommend: Semi-automatic transmission, operating principle.

If the engine is carburetor, it is worth checking the functionality of the ignition coil. It is tested by analogy with spark plugs: its central wire is disconnected, the contact end of which is located a few millimeters from the car body. When the starter is cranked, the wire should spark. If this is not observed, the coil is faulty, or it is necessary to diagnose the performance of the distributor.

Signaling

If you cannot start the engine, you should pay attention to the car alarm. Many modern cars are equipped with immobilizers that prevent the power unit from operating until the owner performs certain actions (pressing a button on the key fob, applying a “pill”, etc.). If you can’t start, it’s possible that the immobilizer protection has simply not been removed.

A car alarm can block the engine on its own if there is some kind of malfunction in its main unit.

The starter turns, the relay does not work

Another sign of a defect when starting the car: the starter turns idle, the crankshaft stands still. In this case, the bendix no longer engages with the flywheel, and here, too, there are several possible breakdowns:

- Bendix teeth are worn (broken);

- the solenoid relay (VR) does not work;

- Bendix spins on the shaft.

If the starter turns, the relay does not work, most likely the VR contacts are burnt, there is not enough lubricant on the surface of the core. Also, a sign of a malfunction of the “retractor” may be repeated cranking (with a buzzing) of the Bendix at idle, and the motor catches only after several attempts to start. The solution to the problem here is achieved in two ways:

- replacing the old BP with a new spare part;

- disassembling the relay with washing the parts and cleaning the contacts.

If the car has stalled somewhere far on the highway and stubbornly does not want to start (it is running in vain), you can try to start it using “tricks of war”:

- when idling, without allowing the Bendix to stop completely, turn the ignition key again all the way to the right, repeat this several times;

- With the engine stopped, gently tap the auxiliary relay housing with a hammer, then try to start the engine;

- Turning on the ignition, use a screwdriver to directly close the BP and main “plus” contacts on the starter, not forgetting to put the car in neutral gear.

Also, “idling” cranking of the starter can occur due to a worn or broken Bendix fork (lever), although such a malfunction is not typical and does not occur so often.

How does the engine start?

The internal combustion engine only operates if the following conditions are met:

- A sufficient amount of fuel and air mixture enters the engine cylinders.

- At the right moment (and to be precise, after the air-fuel mixture is compressed), the spark plug produces a high-power spark.

- The camshaft and crankshaft rotate at the required frequency, which is strictly selected. Only in this way does the gas distribution system work correctly and the chambers are filled with a combustible mixture in a timely manner.

When the driver turns the ignition key, voltage is applied to the starter relay, thereby activating the electric motor. Its function is to engage the flywheel with the crankshaft. Then the crankshaft begins to rotate, its angular momentum is converted into reciprocating movements of the pistons.

When the cylinders begin their work, this subsequently leads to the movement of the camshaft. The latter is needed in order to promptly open the valves to fill the combustion chambers with the mixture.

Camshaft

We recommend: 5 best anti-corrosion products

The internal combustion engine power system is responsible for the timely delivery of the combustible mixture. As soon as the piston moves to the upper compression point, high voltage is applied to the spark. Thus, when the mixture is ignited, a small explosion is created, the expanded gas affects the piston and it moves, moving the crankshaft. We have described the principle of starting an internal combustion engine; remember that engine modifications may be different, so the starting algorithm may differ.

Operation of an internal combustion engine