Causes and symptoms of malfunctions

There are several reasons why the VAZ-2114 steering rack needs to be replaced:

- Natural wear and tear of components;

- Wear due to foreign particles (sand, dirt) getting inside the mechanism;

- Damage to the rack or pinion teeth.

Natural wear and tear is understandable. If a car has driven more than 100 thousand km (and on our roads maybe less), then play in the steering is a common occurrence. But other causes of malfunctions are influenced by the features of operation and maintenance.

Damaged boots and oil seals, careless operation of the car, ignoring adjustment work - all this significantly reduces the life of the steering mechanism and leads to damage that makes further use of the unit impossible.

A worn or faulty VAZ-2114 steering rack will definitely manifest itself, and the symptoms can be different:

- Increased free play in the steering;

- Knocks from the steering rack when driving over uneven surfaces;

- Strong vibrations in the steering wheel;

- The car pulls in different directions;

- Crunching in the area of the steering mechanism when turning;

- Wedging;

- "Weighting" of the steering wheel.

Since many symptoms are also inherent in problems with other components of the VAZ-2114 steering, before making a replacement, you should first make a diagnosis.

It comes down to checking the camber/toe angles, the condition of the rod ends and silent blocks, as well as the column shaft and its components.

Symptoms of a problem

There are typical signs that can be used to diagnose a faulty car steering rack. If it is paired with power steering, it is important to distinguish between its breakdown and the rack mechanism. The main faults of the rack correspond to a specific symptom from the following list:

- Knocking in the rack is characterized by two types:

- Superficial - is a consequence of a rupture of the traction boot, and as a result of dirt getting inside, the tip quickly wears out, a backlash is formed, and knocking begins;

- Internal - indicates a more serious malfunction inside the rack mechanism, the cause of which is difficult to determine without disassembling the unit.

- Backlash in the rack. It can be caused by play in the steering rod joints, the central tooth of the shaft on the rack or the crayon, wear of the silent blocks attached to the body, mechanical damage and other reasons.

- Vibration of the steering wheel when driving straight and on a not too smooth road, which weakens or disappears when turning the steering wheel in any direction.

- The steering wheel does not return to its original position or rotates poorly if the shaft or rack housing is bent.

- The steering wheel rotates tightly and a characteristic whistle is heard. This can happen when the drive belt is loose, the rotor pair is heavily worn, or the power steering fluid level is below the minimum level.

- Steering rack leaking. It appears when rubber seals fail. This is a typical breakdown of a steering system equipped with power steering, in which the fluid in the power steering system is lost daily, and to replenish its level it is necessary to frequently top up.

- The hum of the rack (mechanism) occurs when the circulation of fluid in the power steering system is disrupted, and the steering wheel is difficult to turn. Such signs indicate a failure of the pump, which is not able to create the required pressure.

When is replacement carried out?

If the condition of the listed elements does not cause any complaints, and adjustment work cannot be performed due to backlash, the fault lies in the steering mechanism itself.

Increased free play and knocking can still be eliminated by adjustment. While under the car on the mechanism body, you can find an adjusting screw for a special key, which can be replaced with a 17mm hexagon.

Using a wrench, tighten the screw until it stops, and then unscrew it by ? revolutions, and check the “heaviness” of the steering wheel. It should rotate easily, then you can check the behavior of the steering on the road.

If the adjustment does not help, the play and knocking remain, the VAZ-2114 steering rack needs to be repaired or replaced.

Read on the topic: The play in the steering, what it should be, is normal.

But if there is a crunch in the rack, you can immediately start replacing it, since adjustment with such symptoms obviously will not help.

Replacing the VAZ-2114 rack can be entrusted to service station specialists, but you will have to pay. The cost of replacement services at service centers varies from $20 to $45. And if we add the price of the rail itself, then the amount comes out to be considerable.

You can replace everything yourself, saving on this, especially since performing the operation on a VAZ-2114 is not difficult and even a novice car enthusiast can do it.

Also read about the causes of knocking when turning the steering wheel.

Steering rack for VAZ 2114: replacement, tools

An experienced technician can identify a malfunction in a car by sound. If you hear a knocking noise coming from under the front axle that gets worse over time, then it’s time to check the steering rack. However, when the damage is serious, noticeable vibration is transmitted to the steering wheel. If you ignore this problem, the mechanism will become loose and make driving impossible. The defect only appears on uneven road surfaces, so it will be quite easy to identify. This article describes in detail how to replace the steering rack of a VAZ 2114, signs of a malfunction of this unit, as well as the causes of failure.

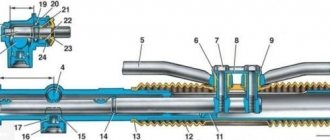

By opening the car's service manual, you can find a diagram of the steering device. From the steering wheel comes a shaft that goes into the steering rack. Dismantling work takes place in the interior and engine compartment. The rack structure includes the following main elements:

- Cardan joint.

- Steering shaft.

- Protective boot.

- Rail body.

- Steering gear housing.

Repair or replacement?

A knock in the steering wheel is just one of the signs of a broken unit. Also, if the rack is faulty, smudges appear on the steering shaft, and stains of working fluid remain in places where the car is parked for long periods of time. Having accurately determined that the problem is in this part, motorists are faced with the question of whether to buy a completely new mechanism or try to repair it on their own. The second option should be chosen only if there is not enough finance to purchase a new unit.

If the choice is made towards repair, then the replacement parts must be new and, most importantly, with a guarantee. You can install new elements yourself or in a car workshop. Having taken out the rack, you need to disassemble it and determine which parts are damaged, and then replace them.

- To remove and install a new part, you must have:

- Hex key set to “17”.

- Jack.

- A set of keys.

- Special puller for tie rod mounts.

- Litol.

- WD-40.

Of course, the replacement will not be completed without a new steering rack set. Motorists recommend installing a unit from a VAZ 2115 for two reasons: it is easy to find a new kit, the parts are more durable than in previous models. It is also worth purchasing new tips. Here preference can be given to third-party manufacturers, for example, Kroner.

Advice! In order not to waste time and money on repairing or replacing the rack, you must adhere to simple rules: the steering wheel should not be in the extreme position for more than 5 seconds. Also, do not spin the engine when the steering wheel is in the extreme position, as this will lead to wear on the rack, gearbox and breakdown of the seals.

Replacement instructions

The work can be done in a garage, box or outdoors. Apart from a jack, no other special equipment is required. The replacement takes place according to the following scheme:

- While the car is standing on a level surface, you need to unscrew the bolts securing the front wheels. After this, the car needs to be jacked up and then the wheels hung;

- The wheels can now be removed. As for the nuts, it is recommended to treat them with WD-40 in order to quickly tighten them;

- Next, you need to move into the interior and remove the locking bolt that holds the steering cardan;

Remove the wheels and treat the lug nuts with WD-40 - Returning to the hood again, you need to unscrew the absorber. This step is optional, but the presence of an absorber will significantly complicate access to the desired mechanism;

- The next step is to remove the tip nut; this action is performed using a cotter pin. After this, the tip can be knocked out. The main thing is that the hammer does not hit the thread, since several blows can completely ruin the part;

- Next you need to remove the steering rods. If a puller is not available, then as an alternative you can use a powerful pry bar and a hammer;

- After these operations, access to the rail appears. It needs to be pulled out from the right side; the rail is secured with two nuts. Next, it needs to be removed from the splines. Here you will need a hammer again. There is no need to hit it hard, as the part comes out easily. Done, the rail along with the tips has been completely dismantled, all that remains is to install a new part;

- After placing the unit on the oilcloth, you need to remove the tips.

An important point is to count the number of turns on the part - it is recommended to write down the result. It's also worth remembering which side each tip was on; Under the hood, unscrew the absorber, this will make the work easier and give you access to the steering rack - Now you need to take a new rail, remove the side plugs, and then fill the free holes with lithol. After this, new tips should be screwed on;

- Installation is done in reverse order, but it is best done with a partner.

Advice! It is necessary to supervise all work at the service station, especially when it comes to the steering mechanism. When performing wheel alignment, it is necessary to loosen the boot clamps; sometimes the craftsmen forget to tighten them back.

The most interesting

Published October 13, 2016

VAZremont.com

Changing the rack yourself

There are two ways to replace the rack. The method is selected based on why exactly the mechanism is being removed - for replacement or repair.

In the case of installing a new rail, you should first determine its completeness.

They go on sale both assembled with steering rods and without them.

The first replacement option involves pressing out the tips from the steering knuckles, so the work will require a special puller.

Tools and accessories

To carry out the replacement you will need:

- Socket or open-end wrenches for 10, 13, 17, 22 (but better - heads with a knob equipped with a ratchet mechanism);

- Jacks and supports;

- WD-40 product;

- Flat screwdriver;

- Hammer;

- Rags;

- Tip remover (if the rods are also dismantled).

Work technology

Let's look at how to replace the VAZ-2114 steering rack without changing the rods. The technology for carrying out the work is as follows:

- We put the car on a flat area or hole, immobilize it (tighten the handbrake, put wheel chocks under the rear wheels);

- Loosen the wheel bolts;

- Using jacks, we hang up the front of the car, then secure it with props. If you have one jack, first lift one side, put a support, remove the lifting mechanism and go to the other side;

- Remove the front wheels;

- In the arch on the left side, in the direction of travel of the car, there is a technological hole that can be covered with a lid (not always). We dismantle this cover;

- If there is an absorber, loosen the clamp securing it, pull out the element and move it to the side;

- Using a hammer and a screwdriver, we bend the antennae of the plate, which prevent the bolts securing the rods to the rack from loosening (for ease of work, you can turn the steering wheel to position the rack in a place that is easy to access);

- We unscrew the fastening bolts and pull them out together with the fixing plate;

- We move the rods to the side;

- In the cabin, in front of the front shield, at the bottom we find the junction of the column shaft with the gear shaft of the mechanism. Unscrew the fixing bolt. By moving the steering wheel towards you, we move the connection;

- Using a 13mm socket, unscrew the nuts securing the brackets that secure the mechanism. They should be treated with WD-40 first, as they often rust. Attempts to unscrew without pre-treatment may lead to breakage of the pin;

- Remove the staples;

- We move the mechanism towards the engine so that the gear shaft completely comes out of the hole in the shield;

- We pull out the assembly through the technological hole;

- We push the new mechanism through the hole, correctly place it, fix it and connect it to the column.

Reassembling the steering control is done in the reverse order of removal.

How it's done

The sequence of actions is as follows:

- Place the car on a level surface and immobilize it;

- It is better to jack up the car on the left side;

- Using open-end wrenches, unscrew the bolts securing the steering rods to the rack, having first bent the fixing plate;

- In the cabin, under the steering column, unscrew the bolt securing it to the steering gear shaft;

- Unscrew the 4 nuts securing the mechanism, and then remove the fastening clamps;

Unscrew the rack bolts

- We pull the mechanism onto the engine so that the gear shaft comes out, and then remove it through the technological hole in the left fender liner;

- With the mechanism removed, remove the retaining ring and rack bushing. Using a screwdriver, loosen and remove the clamps securing the protective cover, as well as the clamp of the protective cap on the right side of the mechanism. Then the cover and cap are removed;

- We unscrew the adjusting nut, which adjusts the gap;

- Rotating the gear shaft to the right, move the rack to the left and remove it. Then press out the rack bushing;

- If the gear is also being changed, then remove the boot from the gear housing, remove the sealing and retaining rings, the bearing, the gear itself and the roller bearing;

- We perform assembly in complete reverse order. At the same time, we change all worn-out elements, as well as consumables - boots, bushings, etc. Be sure to lubricate everything. After assembly, all that remains is to put the mechanism in place and attach the steering gear and rods to it. This is the entire sequence of restoration work with the mechanism with your own hands;

The nuances of replacing the assembly assembly

In the case of replacing the VAZ-2114 rack assembly with rods, we proceed somewhat differently.

There is no need to unscrew the rods from the rack during the work. But you will have to disconnect the tips from the stand. This operation will not be difficult if you have a puller.

If it is not available, you can use the folk method;

- Unbend and remove the stopper;

- Unscrew the tip nut;

- We take the pry bar and place it between the rod and the protrusion of the stand, to which the tip is attached;

- We use a pry bar to create a pressing force and at the same time apply sharp blows with a hammer to the protrusion (usually 2-3 blows are enough for the tip to “pop out”).

Next, we do everything identical to what was described: unscrew the fastening nuts and the fixing bolt on the column shaft. Afterwards all that remains is to remove the mechanism and replace it with a new one.

After replacement, it will be necessary to adjust the camber/toe angles of the VAZ-2114 steering, even if the rods were not removed. This operation will definitely not be superfluous.

Diagnostics and restoration of slats

Instead of purchasing a new rack, you can try to repair the one installed on the car. But first you need to make a diagnosis.

To do this, we completely disassemble the assembly into its component parts and carry out troubleshooting. This will allow you to determine which elements are extremely worn or damaged.

Repair kits for restoring the steering mechanism are sold on the market. Moreover, their completeness is very different.

Some include only rubber and plastic elements (oil seals, boots, bushings).

Others come with a new rack, gear, connecting elements, bearings (in general, almost all components).

With the help of repair kits, you can restore the functionality of the “native” unit, but only on the condition that the body is intact and does not have significant wear.

The use of repair kits can significantly reduce the cost of repair work. But they do not always allow you to restore functionality and problems with the steering remain even after repairs.

In this case, there is only one way out - replacing the steering rack with a new one.

Signs of steering rack failure

To fix a problem with the steering rack, accurate diagnostics will be required. A steering rack test stand will help you quickly and accurately diagnose a breakdown, but to do this you need to visit a car service center.

If the driver knows the main faults of the steering rack, it will be possible to avoid replacing the steering rack. Signs of mechanism destruction:

- A knocking sound in the steering rack (play);

- Oil leakage;

- Difficulty turning wheels;

- Difficulty with control (hard steering).

To test the steering rack, you need the help of specialists and diagnostic equipment from MSG Equipment. It is impossible to replace the steering rack if there is some damage, then the rack is replaced with a new one. Diagnostics of the power steering pump is carried out at the MSG Equipment stand if there is a suspicion of a faulty power steering. Remember that even minor problems with power steering can cause an accident, so do not try to check the operation of the mechanism yourself.

Selecting a replacement unit

The choice of a new unit for the VAZ-2114 should be approached seriously. The main problem is that very often there are defective products on the market that are already faulty or will fail in a very short time.

The best option is to purchase an original unit. The VAZ-2114 uses the same mechanism as the cars of the Samara 1 family (2108, 2109, 21099). Therefore, its catalog number is 2108-3400012, that is, when searching, you can safely ask for a rack for the “Eight” and not worry that it will not fit. The average cost is $100.

You can also buy analogue racks produced by auto parts manufacturers. But here you should pay attention to the manufacturer (it must be well-known), as well as the availability of quality certificates.

Among analog products, we recommend paying attention to steering mechanisms from the following manufacturers:

- Weber CG 2108-0012 (its price starts at $80);

- Pilenga SR-P 1141 (costs $100);

- Trialli CR 108 and CR S 708 (the first comes without rods and lugs and costs about $100, the second has an assembled mechanism, which is why it costs twice as much).

For those who want to slightly modify the steering, you can look for tuning racks. The main difference between them is the lower number of revolutions. They are also positioned by manufacturers as reinforced.

Regarding manufacturers, it is worth looking for products from the Italian company Brembo, the Polish company ATF, or the Russian company SS20.

As for the latter manufacturer, it only produces steering racks for the 10th VAZ family, so after acquisition the mechanism will have to be slightly altered.

But we note that tuning slats will cost much more than the original or conventional analogues. So, for a Brembo unit you will have to pay about $250, for ATF - about $200, and SS20 - approximately $210-220.

New or refurbished?

Among car enthusiasts, the question often arises regarding the steering rack - should I purchase a new one for replacement or restore the “original” one? It is impossible to answer unequivocally here.

If the repair was carried out independently and using a high-quality repair kit, then after restoration the rack can serve for quite a long time.

But if you purchase a restored rack or if it is repaired at a service station, there is a high probability that problems will soon arise. After all, it is unknown who, how and with what help carried out the restoration.

As for new units, there are a lot of defective racks on the market.

In general, it is still better to try to repair the rack first, since it is much cheaper. It is worth purchasing a new mechanism only after you have already become convinced that the restoration did not help.