At first glance, the crankshaft toothed pulley seems to be an unimportant part, but despite this, the functioning of many vehicle systems depends on it. It is used not only in passenger cars, but also in lifting and construction equipment. The need to replace it often arises when installing a new crankshaft oil seal, as well as when the pulley structure is damaged.

Description

Many vehicle systems operate using energy supplied from the crankshaft. The design of the pulley has improved over time; today several options have appeared, each of which is suitable for a specific vehicle and various operating conditions. They are fixed using bushings made of high-quality materials, thus simplifying installation and increasing the reliability of fastening.

The main purpose of a pulley is to transfer energy between shafts. It is of particular importance in the following cases:

- there is excessive transmission load on the belt;

- It is necessary to prevent belt slippage.

Crankshaft pulley - why is a car “dead” without it?

A detail that does not catch the eye and seems insignificant, actually plays an important role in ensuring the functionality of all vehicle systems. Having a fairly simple and reliable device, the crankshaft pulley sometimes needs to be replaced. Most often it is removed when it is necessary to replace the crankshaft oil seal. In this regard, it is important to know what types of pulleys exist, what can cause breakdowns, and how replacement is made.

Types of pulleys for the crankshaft

The vast majority of car mechanisms use energy received from the rotating crankshaft to operate. If the rotation of the wheels is ensured by a whole system of shafts and gears, then a crankshaft pulley is used to drive the gas distribution mechanism (GRM), generator, pump, air conditioner.

In different periods of the automotive industry and for different brands of cars, pulley design solutions independent of each other were used. It makes no sense to say which type of pulleys is better; for different operating conditions of the car there is a different type of pulley.

Crankshaft with pulley for V-belt

Almost all cars, trucks, and buses with engines developed by domestic designers in the Soviet era are equipped with a belt drive for the generator. The pulley for such a belt has an all-cast (all-welded) design, and the groove repeats the configuration of the V-belt.

The pulley is mounted on the end of the shaft through a key, which prevents it from turning, and is secured with a nut (less commonly, a bolt). The simplest design allowed the pulley to be used throughout the entire period of operation of the motor.

Crankshaft Timing Pulley

In order to facilitate the gas distribution system and wire, the designers proposed using a belt rather than a chain. A similar design is found on almost all modern cars. In order to achieve maximum coincidence of the angle of rotation of the crankshaft and camshaft, the inner surface of the belt has grooves, and teeth are applied to the outer rim of the pulley. That is why such a pulley is called toothed. Provided timely replacement of belts and proper operation, the pulley itself lasts quite a long time, and breakdown is rare.

Crankshaft damper pulley

At the moment of startup and a sharp change in crankshaft rotation speed, the belt and gas distribution system are subjected to a strong impulse mechanical effect. The developers proposed equipping the pulley with a damper - a rubber layer between the inner race and the outer working disk. This design has found wide application in engines for minibuses and light-duty vehicles.

The designers achieved the desired result, but at the same time significantly reduced the life of the pulley. Rubber loses its elasticity and breaks down due to temperature changes, aggressive environments, and mechanical loads. Car owners are forced to continuously monitor the condition of the damper and urgently change the pulley if defects appear. Sometimes the pulley breaks, completely immobilizing the car.

How to replace a crankshaft pulley

Whatever design the pulley is used on the motor, the principle of dismantling and installation remains the same. If the motor is located along the engine compartment, then the pulley is located in the lower front part, behind the cooling radiator. If the block is located transversely, the pulley can be accessed by removing the right front wheel.

The most frequently asked question on auto forums is: what thread is on the crankshaft pulley? The problem is that the nut or bolt is too tight. Experiencing serious difficulties during dismantling, car owners doubt the correct direction of their efforts.

In this case, there is only one answer - the thread is right-handed, that is, the nut (bolt) must be unscrewed counterclockwise. The crankshaft rotates in the opposite direction, which results in a gradual, strong tightening. If we add to this the processes of oxidation and corrosion, then it is very difficult to remove such a tightening by hand.

Knowing some techniques, the whole process can be reduced to 10 minutes. The algorithm of actions is as follows:

- the car is installed on the inspection hole, the wheels are fixed with stops;

- when the block is positioned transversely, the wheel is removed and a “tragus” is placed under the brake disc;

- a socket wrench with an extended lever is put on the head of the crankshaft bolt (nut) and rests against the floor in the direction of rotation;

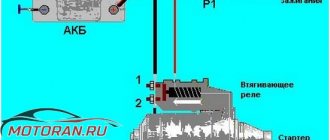

- the armored wire is removed from the ignition distributor so that the engine does not start;

- By briefly turning on the ignition, the starter is activated, the force of which is usually sufficient to tear off the bolt (nut).

This technique can be repeated several times until the puff is released. Next, unscrewing is done manually. To facilitate the process, it is recommended to cover all joints of parts with a layer of WD type lubricant or brake fluid in advance.

Pulling the pulley off the crankshaft is also not easy. Firstly, the landing dimensions are selected for the most durable connection and elimination of backlash. Secondly, the crankshaft pulley key also provides resistance due to the tight fit. It is ideal to use a special screw puller. In the absence of such devices, the pulley is removed using a pry bar, gently pressing on the back surface of the pulley in different places.

If the car owner managed to dismantle the pulley, then there will be no problems with its installation. Everything happens in the reverse order, and the crankshaft will provide itself with reliable clamping.

How to choose

When choosing a toothed pulley, you should pay attention to the processing class, the distance between the teeth and the manufacturing shape. The tooth surfaces and the belt are subject to constant loads, so high demands are placed on the quality of cutting and processing. Cutting teeth is carried out in several stages on a milling machine or devices designed specifically for the manufacture of these parts. Cast iron products are somewhat different from other varieties; they are cast in forms that completely replicate finished pulleys for timing belts and are processed using a milling machine.

The flanges on the pulley can be either absent or located on one or both sides. They are fixed in three ways:

- riveting with further milling;

- bolted connections;

- Shrink fit (used only for small part sizes).

Materials

Before purchasing a product, you need to determine the materials that were used in its manufacture. The most common ones are cast iron, aluminum and steel. Cast iron is gradually fading into the background, since it is inferior in characteristics to modern alloys, and is also quite expensive. A toothed pulley made of low-alloy steel, which is resistant to corrosion, wear, mechanical damage and can be subjected to heat treatment, has become quite widespread.

The calculation of gear and belt transmission is carried out in a similar way, but the elastic belt acting as a transmission body must be taken into account. There are two main types of calculation: metric and imperial. The calculation of the required number of teeth depends on the number of teeth and the gear ratio. In some cases, it is possible to use idler rollers to provide greater traction.

Dismantling

In order to remove the old toothed pulley, it is necessary to remove the cover that hides the wires of the units, thus providing free access to the motor parts that require replacement. Next, the tension of the drive chain is released. After which the tank with antifreeze liquid and the electric generator are removed. If the car is equipped with power steering, it is necessary to remove the belt for this system.

Next, all that remains is to remove the mounting bolt that secures the toothed pulley to the crankshaft, but difficulties may arise here due to the direction of the thread. While the engine is moving, the bolt is constantly tightened, so at this stage of the work a pneumatic impact wrench may be required if the manual effort is not enough.

In the absence of special tools that significantly simplify the task, it is recommended to secure a wrench to the bolt to prevent it from turning. During work, the vehicle must be on jacks or with the drive wheels removed. This is necessary to ensure that the transport does not move from its place. The bolt will be unscrewed by sharply turning the ignition key, while the starter will make several turns and all that remains is to remove the bolt. After replacing the pulley, all parts are installed in the reverse order.

Where is the crankshaft pulley located and how to get to it?

When you lift the hood and glance at the engine, the crankshaft damper pulley (as well as the regular one) is almost invisible. It is hidden by the generator, but looking down where the belt runs, you can see a disk tightly fixed to the shaft with a hub. This is the part you are looking for. Pulleys come in two types, regular and with a damper, and the latter option is distinguished by the presence of an external massive ring, separated from the main part by a rubber gasket, to reduce vibration of the part . Along the outer edge of the damper there are teeth cut, necessary for the operation of the crankshaft position sensor.

To remove the pulley, you must first loosen the locking bolt on the generator, then loosen the tension bolt so that you can slightly release the belt and be able to remove it. We also disconnect the antifreeze reservoir. The power steering belt may also be in the way, so to the side of the pulley we find and unscrew the 14 bolt that creates tension on the power steering transmission, and then remove the latter. There remains the final step that separates us from success, and the most difficult one is to unscrew the one more bolt that secures the pulley. You can find the fastening element only by looking under the car under the right front wheel, and if you have a pneumatic impact wrench, the operation will be completed without difficulty.

What to pay attention to

Removing the VAZ toothed pulley from its seat is also quite difficult. Torque is transmitted through a keyed connection, and the pulley itself is attached using a transition fit. It is advisable to have a special puller with you that will ensure smooth dismantling of the part with a minimum of effort. If difficulties arise, you can treat the connection with WD-40. When removing, it is important not to damage the keyway, so you need to act carefully and slowly. If this rule is not followed, there is a risk of chips and small cracks.

Why is it difficult to remove the crankshaft timing belt?

In the absence of a special tool, removing the bolt holding the crankshaft toothed pulley is very problematic, since the thread is cut so that the direction of unscrewing coincides with the torque of the shaft when the engine is running. However, this is precisely the way out of the situation. All you need is a long wrench with a 19-mm head (can be extended with a piece of pipe), which rests against the ground against the rotation of the shaft. We carry out small preparatory work - we place wedges under the front wheels, and disconnect the connector on the ignition coil. For what? To use the starter as a mechanical force applied to the bolt.

So, we have done everything to prevent the car from accidentally starting and moving away. Now we ask everyone present to move away, while we ourselves climb into the cabin (do not leave your legs sticking out) and sharply, but briefly, turn the ignition key to start. If an attempt fails, do not despair and repeat. Usually the second time, less often after the 5th or 6th attempt, the bolt turns. Now you can proceed to the next step - removing the pulley hub from the shaft, taking into account that it fits tightly and is held in place by a key. When you need to tighten the bolt back, you either need to put a lot of force into tightening it, or still find an air impact wrench by then.